We Put Our Best Face Forward

The fibres we choose have a big job to do—work hard, lower our environmental impact and look beautiful for a very long time. So, we purchase premium, solution dyed fibres with a low modification ratio to ensure long-lasting performance. And, of course, we choose fibres with the highest recycled content possible (post-consumer and post-industrial) to lower the environmental impact of our products.

More Than Skin Deep

Solution dying injects fibre with colour throughout, like a carrot. Non solution dyed fibre only has colour on the surface, like a radish. Solution dyed colour lasts longer, resisting most bleaches and other harmful liquids as well as sun exposure. And with our Protekt2™ stain resistant technology built into the fibres, you’ve got added protection against staining with no need for an additional topical treatment.

Shape Matters

Modification ratio estimates a fibre’s performance by how “round” it is. A larger, rounded core decreases the potential for crushing and wear, keeping fibres easy to clean. The concave aspects around the core provide strength while helping to hide soiling. In short, the fibre with the larger diameter performs better. The fibres we use have a modification ratio of 2.2 or less, whereas mill extruded Type 6 Nylon has a ratio of 2.5 or more.

Low vs. Higher Modification Ratio Fiber

To illustrate the superior performance of the fibres we use, we ran a 10-year wet and dry ART test on an Interface product made with fibre that had a modification ratio of less than 2.0, along with a competitor’s product made with fibre that had a modification ratio of greater than 2.5. See the before and after images of the length of the fibres. Notice the abrasion and breakdown of the fibre in the competitive product as compared to the Interface product.

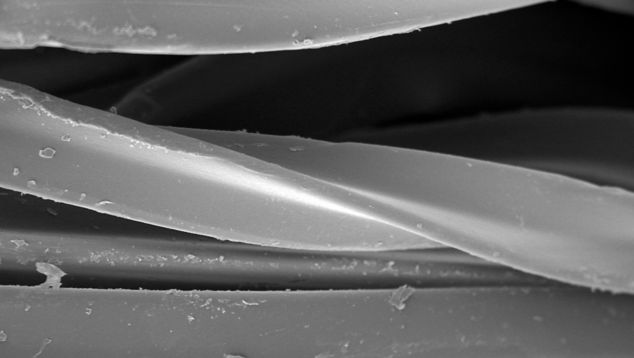

Length of low modification ratio fibre before testing.

Length of low modification ratio fibre after testing: some minor distortion of the fibres can be seen but overall the rounded shape is intact.

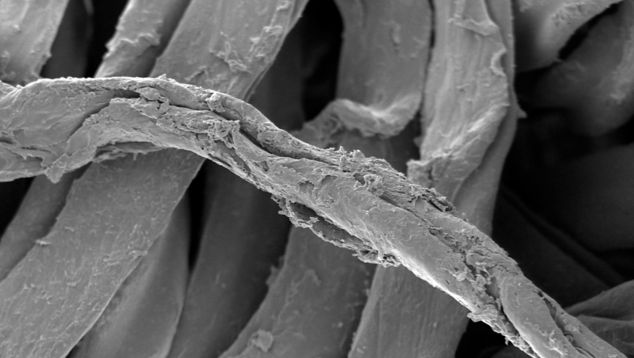

Length of high modification ratio fibre viewed before testing.

Length of high modification fibre viewed after testing: The fibres have been destroyed. The tall peaks have flattened out and created deep valleys within the surface that trap and hold soil.